Kev kub ceev motorstau txais kev saib xyuas ntau ntxiv vim lawv qhov txiaj ntsig zoo xws li lub zog loj, qhov loj me thiab qhov hnyav, thiab kev ua haujlwm siab. Kev ua haujlwm zoo thiab ruaj khov tsav yog tus yuam sij rau kev siv tag nrho cov kev ua tau zoo ntawmhigh-speed motors. Kab lus no feem ntau tsom xam cov teeb meem ntawmhigh-speed lub cev muaj zogtsav cov thev naus laus zis los ntawm cov yam ntxwv ntawm kev tswj lub tswv yim, kev kwv yees kaum sab xis, thiab lub zog topology tsim, thiab sau cov ntsiab lus tshawb fawb tam sim no hauv tsev thiab txawv teb chaws. Tom qab ntawd, nws xaus lus thiab prospects txoj kev loj hlob ntawmhigh-speed lub cev muaj zogtsav tshuab.

Part 02 Kev Tshawb Fawb Cov Ntsiab Lus

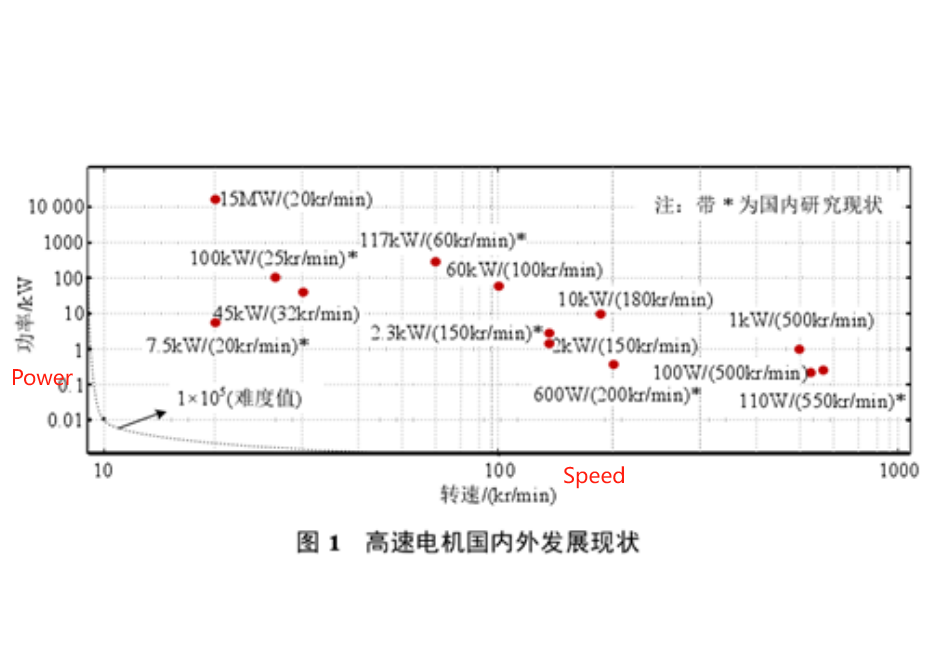

Kev kub ceev motorsmuaj ntau yam zoo xws li lub zog loj, qhov ntim me me thiab qhov hnyav, thiab kev ua haujlwm siab. Lawv tau siv dav hauv kev lag luam xws li aerospace, kev tiv thaiv hauv teb chaws thiab kev nyab xeeb, kev tsim khoom thiab kev ua neej nyob txhua hnub, thiab yog qhov tsim nyog tshawb fawb cov ntsiab lus thiab kev txhim kho kev coj ua niaj hnub no. Nyob rau hauv high-ceev load daim ntaub ntawv xws li hluav taws xob spindles, turbomachinery, micro roj turbines, thiab flywheel zog cia, daim ntawv thov ntawm high-ceev motors yuav ua tau ib tug ncaj tsav qauv, tshem tawm txawv txawv ceev li, txo ntim, hnyav, thiab tu nqi. , thaum txhim kho kev ntseeg tau zoo, thiab muaj kev thov dav dav heev.Kev kub ceev motorsfeem ntau yog xa mus rau qhov nrawm tshaj 10kr / min lossis qhov nyuaj (cov khoom lag luam nrawm thiab lub hauv paus ntawm lub zog) tshaj 1 × Lub cev muaj zog ntawm 105 yog qhia hauv daim duab 1, uas piv cov ntaub ntawv cuam tshuam ntawm qee tus neeg sawv cev ntawm cov motors high-speed ob qho tib si hauv tsev. thiab thoob ntiaj teb. Cov kab dashed hauv daim duab 1 yog 1 × 105 theem nyuaj, thiab lwm yam

1,Nyuaj nyob rau hauv High Speed Motor Drive Technology

1. Cov teeb meem kev ruaj ntseg ntawm lub hauv paus loj

Thaum lub cev muaj zog nyob rau hauv kev ua haujlwm siab ntawm lub xeev zaus, vim muaj kev txwv xws li lub sijhawm hloov pauv ntawm analog-rau-digital, lub sijhawm ua haujlwm digital tswj lub sijhawm, thiab inverter hloov zaus, cov cab kuj zaus ntawm lub siab ceev tsav lub cev muaj zog kuj tsawg. , ua rau muaj qhov txo qis hauv kev ua haujlwm ntawm lub cev muaj zog.

2. Qhov teeb meem ntawm high-precision rotor txoj hauj lwm kwv yees nyob rau hauv lub hauv paus zaus

Thaum lub sijhawm ua haujlwm siab, qhov tseeb ntawm txoj haujlwm rotor yog qhov tseem ceeb rau kev ua haujlwm ntawm lub cev muaj zog. Vim qhov tsis tshua muaj kev ntseeg siab, qhov loj me, thiab tus nqi siab ntawm cov khoom siv hluav taws xob, sensorless algorithms feem ntau yog siv rau hauv high-speed motor control systems. Txawm li cas los xij, nyob rau hauv qhov kev ua haujlwm siab ntawm cov zaus zaus, kev siv txoj haujlwm sensorless algorithms yog qhov cuam tshuam rau cov yam tsis zoo xws li inverter nonlinearity, spatial harmonics, voj lim, thiab inductance parameter deviations, ua rau qhov tseem ceeb rotor txoj hauj lwm kwv yees yuam kev.

3. Ripple suppression nyob rau hauv high-speed lub cev muaj zog tsav tshuab

Qhov me me inductance ntawm high-ceev motors inevitably ua rau muaj teeb meem ntawm loj tam sim no ripple. Qhov ntxiv tooj liab poob, hlau poob, torque ripple, thiab vibration suab nrov tshwm sim los ntawm kev kub siab tam sim no ripple tuaj yeem ua rau muaj kev poob siab ntawm lub cev muaj zog, txo cov kev ua haujlwm ntawm lub cev muaj zog, thiab cov khoom siv hluav taws xob cuam tshuam los ntawm kev co suab nrov tuaj yeem ua rau kev laus ntawm lub cev muaj zog. tus tsav tsheb. Cov teeb meem saum toj no cuam tshuam rau kev ua tau zoo ntawm kev ua haujlwm siab ntawm lub cev muaj zog tsav, thiab kev tsim kho kom zoo ntawm cov khoom siv hluav taws xob tsawg tsawg yog qhov tseem ceeb rau kev tsav tsheb ceev ceev. Nyob rau hauv cov ntsiab lus, tus tsim ntawm ib tug high-ceev lub cev muaj zog tsav system yuav tsum muaj kev xav txog ntawm ntau yam, nrog rau tam sim no voj coupling, system ncua sij hawm, parameter yuam kev, thiab kev nyuaj siab xws li tam sim no ripple suppression. Nws yog cov txheej txheem nyuaj heev uas tso siab rau cov tswv yim tswj, rotor txoj haujlwm kwv yees qhov tseeb, thiab lub zog topology tsim.

2 、 Tswj Lub Tswv Yim rau Kev Kub Ceev Tsav Tsav Tsheb

1. Kev ua qauv ntawm kev kub ceev lub cev muaj zog tswj qhov system

Cov yam ntxwv ntawm kev khiav hauj lwm hauv paus zaus thiab tsawg tus cab kuj sib piv nyob rau hauv high-ceev lub cev muaj zog tsav systems, raws li zoo raws li lub hwj chim ntawm lub cev muaj zog coupling thiab ncua ntawm lub system, yuav tsis raug ignored. Yog li ntawd, xav txog ob yam tseem ceeb saum toj no, kev ua qauv thiab tshuaj xyuas kev tsim kho ntawm cov tshuab tsav tsheb ceev yog tus yuam sij rau kev txhim kho kev tsav tsheb ntawm kev kub ceev.

2. Decoupling Control Technology rau Kev Kub Ceev Cov Tsav Tsheb

Cov cuab yeej siv dav tshaj plaws hauv kev ua haujlwm siab tsav lub cev yog FOC tswj. Nyob rau hauv teb rau qhov teeb meem loj coupling tshwm sim los ntawm kev ua haujlwm siab zaus, cov kev tshawb fawb tseem ceeb tam sim no yog decoupling tswj cov tswv yim. Cov tswv yim tswj kev decoupling tam sim no tau kawm tuaj yeem muab faib ua qauv raws li kev tswj hwm kev tswj hwm, kev cuam tshuam kev cuam tshuam raws li kev tswj hwm kev tswj hwm, thiab cov tswv yim kev tswj hwm vector nyuaj raws li decoupling tswj cov tswv yim. Tus qauv raws li kev tswj xyuas cov tswv yim feem ntau suav nrog kev xa tawm kev xa tawm thiab kev tawm tswv yim decoupling, tab sis lub tswv yim no yog rhiab rau lub cev tsis muaj zog thiab tuaj yeem ua rau lub cev tsis ruaj khov thaum muaj qhov tsis zoo loj, thiab tsis tuaj yeem ua tiav decoupling. Qhov tsis zoo dynamic decoupling kev ua tau zoo txwv nws daim ntawv thov ntau yam. Ob txoj kev tswj hwm kev tswj hwm tom kawg yog tam sim no tshawb fawb hotspots.

3. Kev Them Nyiaj Them Nqi Them Nqi Them Nqi rau Kev Siv Hluav Taws Xob Hluav Taws Xob

Kev tswj cov cuab yeej siv tau zoo tuaj yeem daws qhov teeb meem sib txuas ntawm lub tshuab hluav taws xob ceev ceev, tab sis qhov txuas txuas txuas tau nthuav tawm los ntawm kev ncua tseem muaj, yog li kev siv nyiaj ua haujlwm tau zoo rau kev ncua sij hawm xav tau. Tam sim no, muaj ob lub ntsiab lus tseem ceeb rau kev ncua sij hawm: qauv raws li cov tswv yim them nyiaj thiab cov qauv kev them nyiaj ywj pheej.

Part 03 Kev Tshawb Fawb Txog Kev Tshawb Fawb

Raws li cov kev tshawb fawb tam sim no ua tiav hauvhigh-speed lub cev muaj zogtsav tshuab hauv kev kawm hauv zej zog, ua ke nrog cov teeb meem uas twb muaj lawm, kev txhim kho thiab kev tshawb fawb cov lus qhia ntawm high-speed motors feem ntau suav nrog: 1) kev tshawb fawb txog kev kwv yees qhov tseeb ntawm qhov tseem ceeb zaus tam sim no thiab cov nyiaj them poob haujlwm qeeb cuam tshuam txog cov teeb meem; 3) Kev tshawb fawb txog kev ua haujlwm siab dynamic tswj algorithms rau high-speed motors; 4) Kev tshawb fawb txog kev kwv yees qhov tseeb ntawm kaum txoj hauj lwm thiab tag nrho ceev domain rotor txoj hauj lwm kwv yees qauv rau ultra high speed motors; 5) Kev tshawb fawb txog kev them nyiaj thev naus laus zis rau kev ua yuam kev hauv kev ntsuas kev ua haujlwm siab ntawm lub cev muaj zog; 6) Kev tshawb fawb ntawm ntau zaus thiab poob siab ntawm kev kub ceev lub cev muaj zog toyology.

Post lub sij hawm: Oct-24-2023