Cov yam tseem ceeb uas cuam tshuam rau kev siv hlau yooj yim

Yuav kom txheeb xyuas tau ib qho teeb meem, peb yuav tsum xub paub qee cov kev xav yooj yim, uas yuav pab peb nkag siab. Ua ntej, peb yuav tsum paub ob lub tswv yim. Ib qho yog kev hloov pauv magnetization, uas, kom yooj yim, tshwm sim hauv lub plawv hlau ntawm lub transformer thiab hauv stator lossis rotor hniav ntawm lub cev muaj zog; Ib qho yog qhov khoom siv magnetization tig, uas yog tsim los ntawm stator lossis rotor yoke ntawm lub cev muaj zog. Muaj ntau tsab xov xwm uas pib los ntawm ob lub ntsiab lus thiab xam cov hlau poob ntawm lub cev muaj zog raws li cov yam ntxwv sib txawv raws li txoj kev daws teeb meem saum toj no. Cov kev sim tau qhia tias cov ntawv hlau silicon qhia txog cov xwm txheej hauv qab no hauv qab magnetization ntawm ob lub zog:

Thaum qhov ceev ntawm cov hlau nplaum sib nqus qis dua 1.7 Tesla, qhov poob hysteresis los ntawm kev sib hloov magnetization yog ntau dua li qhov tshwm sim los ntawm kev hloov pauv magnetization; Thaum nws siab dua 1.7 Tesla, qhov sib txawv yog qhov tseeb. Qhov ceev ntawm cov hlau nplaum sib nqus ntawm lub cev muaj zog feem ntau yog nruab nrab ntawm 1.0 thiab 1.5 Tesla, thiab qhov poob ntawm kev sib hloov magnetization hysteresis sib xws yog li 45 txog 65% ntau dua li qhov poob ntawm kev sib hloov magnetization hysteresis.

Tau kawg, cov lus xaus saum toj no kuj tau siv, thiab kuv tus kheej tsis tau txheeb xyuas lawv hauv kev xyaum. Tsis tas li ntawd, thaum lub zog sib nqus hauv cov hlau tseem ceeb hloov pauv, tam sim no raug tsim hauv nws, hu ua eddy tam sim no, thiab qhov poob los ntawm nws hu ua eddy tam sim no poob. Yuav kom txo qhov poob eddy tam sim no, lub cev muaj zog hlau feem ntau tsis tuaj yeem ua rau hauv ib lub thaiv tag nrho, thiab raug teeb tsa los ntawm cov ntawv hlau insulated kom cuam tshuam cov dej ntws ntawm eddy tam sim no. Cov mis suav tshwj xeeb rau kev siv hlau yuav tsis nyuaj ntawm no. Cov mis yooj yim thiab qhov tseem ceeb ntawm Baidu hlau siv kev suav yuav meej heev. Cov hauv qab no yog kev tshuaj xyuas ntawm ntau yam tseem ceeb uas cuam tshuam rau peb cov hlau siv, yog li txhua tus tuaj yeem xa mus tom ntej lossis rov qab txiav txim siab qhov teeb meem hauv kev siv engineering.

Tom qab tham txog cov saum toj no, vim li cas kev tsim khoom ntawm kev ntaus ntawv thiaj li cuam tshuam rau kev siv hlau? Cov yam ntxwv ntawm cov txheej txheem xuas nrig feem ntau nyob ntawm cov duab sib txawv ntawm cov tshuab xuas nrig, thiab txiav txim siab hom shear thiab qib kev ntxhov siab raws li qhov xav tau ntawm ntau hom qhov thiab grooves, yog li ua kom ntseeg tau tias cov xwm txheej ntawm thaj chaw ntxhov siab ntiav nyob ib puag ncig ntawm qhov lamination. Vim yog kev sib raug zoo ntawm qhov tob thiab cov duab, nws feem ntau cuam tshuam los ntawm cov ces kaum ntse, mus rau qhov uas cov qib kev ntxhov siab siab tuaj yeem ua rau cov hlau poob ntau hauv thaj chaw ntxhov siab ntiav, tshwj xeeb tshaj yog nyob rau hauv cov ntug shear ntev hauv qhov ntau ntawm lamination. Tshwj xeeb, nws feem ntau tshwm sim hauv thaj chaw alveolar, uas feem ntau dhau los ua qhov tseem ceeb ntawm kev tshawb fawb hauv cov txheej txheem tshawb fawb tiag tiag. Cov ntawv hlau silicon poob qis feem ntau txiav txim siab los ntawm cov noob loj dua. Kev cuam tshuam tuaj yeem ua rau cov burrs hluavtaws thiab tearing shear ntawm ntug hauv qab ntawm daim ntawv, thiab lub kaum sab xis ntawm kev cuam tshuam tuaj yeem muaj kev cuam tshuam loj rau qhov loj ntawm burrs thiab thaj chaw deformation. Yog tias thaj chaw ntxhov siab siab txuas ntxiv mus rau ntug deformation cheeb tsam mus rau sab hauv ntawm cov khoom siv, cov qauv noob hauv cov cheeb tsam no yuav zam dhau qhov kev hloov pauv sib xws, yuav twisted lossis tawg, thiab qhov ntev ntawm ciam teb yuav tshwm sim raws li kev coj ua tearing. Lub sijhawm no, qhov ceev ntawm cov noob qoob loo hauv thaj chaw ntxhov siab hauv qhov kev taw qhia shear yuav nce ntxiv, ua rau muaj kev nce ntxiv ntawm kev poob hlau hauv thaj chaw. Yog li, ntawm lub sijhawm no, cov khoom siv hauv thaj chaw ntxhov siab tuaj yeem suav tias yog cov khoom poob siab uas poob rau saum cov lamination ib txwm raws ntug cuam tshuam. Ua li no, qhov tseeb tsis hloov pauv ntawm cov khoom siv ntug tuaj yeem txiav txim siab, thiab qhov tseeb poob ntawm ntug cuam tshuam tuaj yeem txiav txim siab ntxiv siv cov qauv poob hlau.

1. Kev Cuam Tshuam ntawm Cov Txheej Txheem Annealing rau Kev Poob Hlau

Cov xwm txheej cuam tshuam ntawm kev poob hlau feem ntau muaj nyob rau hauv cov ntawv hlau silicon, thiab kev ntxhov siab thiab thermal yuav cuam tshuam rau cov ntawv hlau silicon nrog kev hloov pauv hauv lawv cov yam ntxwv tiag tiag. Kev ntxhov siab ntxiv yuav ua rau muaj kev hloov pauv ntawm kev poob hlau. Tib lub sijhawm, qhov nce ntxiv ntawm qhov kub sab hauv ntawm lub cev muaj zog kuj tseem yuav txhawb nqa qhov tshwm sim ntawm cov teeb meem poob hlau. Kev siv cov kev ntsuas annealing zoo los tshem tawm kev ntxhov siab ntxiv yuav muaj txiaj ntsig zoo rau kev txo cov hlau poob hauv lub cev muaj zog.

2. Vim li cas thiaj ua rau muaj kev poob ntau dhau hauv cov txheej txheem tsim khoom

Cov ntawv hlau silicon, ua cov khoom siv hlau nplaum tseem ceeb rau cov cav tov, muaj kev cuam tshuam loj rau kev ua haujlwm ntawm lub cav vim lawv ua raws li cov qauv tsim. Tsis tas li ntawd, kev ua haujlwm ntawm cov ntawv hlau silicon ntawm tib qib yuav txawv ntawm cov chaw tsim khoom sib txawv. Thaum xaiv cov ntaub ntawv, yuav tsum tau siv zog los xaiv cov ntaub ntawv los ntawm cov chaw tsim khoom hlau silicon zoo. Hauv qab no yog qee yam tseem ceeb uas tau cuam tshuam rau kev siv hlau uas tau ntsib ua ntej.

Cov ntawv hlau silicon tsis tau raug rwb thaiv tsev lossis kho kom zoo. Hom teeb meem no tuaj yeem pom thaum lub sijhawm sim cov ntawv hlau silicon, tab sis tsis yog txhua tus neeg tsim khoom siv lub cev muaj cov khoom sim no, thiab qhov teeb meem no feem ntau tsis tau lees paub zoo los ntawm cov neeg tsim khoom siv lub cev.

Kev puas tsuaj ntawm cov rwb thaiv tsev ntawm cov ntawv lossis luv luv ntawm cov ntawv. Hom teeb meem no tshwm sim thaum lub sijhawm tsim cov hlau tseem ceeb. Yog tias lub siab thaum lub sijhawm lamination ntawm cov hlau tseem ceeb siab dhau, ua rau puas tsuaj rau cov rwb thaiv tsev ntawm cov ntawv; Lossis yog tias cov burrs loj dhau tom qab xuas nrig, lawv tuaj yeem tshem tawm los ntawm kev txhuam, ua rau muaj kev puas tsuaj loj rau cov rwb thaiv tsev ntawm qhov chaw xuas nrig; Tom qab cov hlau tseem ceeb lamination tiav lawm, qhov groove tsis du, thiab siv txoj kev filing; Xwb, vim muaj cov yam xws li tsis sib npaug ntawm stator bore thiab tsis sib npaug ntawm stator bore thiab lub rooj zaum ntawm lub tshuab, tig yuav siv tau rau kev kho. Kev siv cov txheej txheem tsim khoom thiab ua cov txheej txheem no muaj kev cuam tshuam loj rau kev ua haujlwm ntawm lub cev muaj zog, tshwj xeeb tshaj yog cov hlau poob.

Thaum siv cov txheej txheem xws li hlawv lossis cua sov nrog hluav taws xob los rhuav tshem cov xov hlau, nws tuaj yeem ua rau lub plawv hlau kub dhau, ua rau muaj kev sib nqus hluav taws xob tsawg dua thiab ua rau cov rwb thaiv tsev ntawm cov ntawv puas tsuaj. Qhov teeb meem no feem ntau tshwm sim thaum kho cov xov hlau thiab lub cev muaj zog thaum lub sijhawm tsim khoom thiab ua cov txheej txheem.

Kev vuam stacking thiab lwm yam txheej txheem kuj tseem tuaj yeem ua rau puas tsuaj rau lub rwb thaiv tsev ntawm cov stacks, ua rau muaj kev poob eddy tam sim no.

Qhov hnyav hlau tsis txaus thiab kev sib zog tsis tiav ntawm cov ntawv. Qhov tshwm sim kawg yog qhov hnyav ntawm lub plawv hlau tsis txaus, thiab qhov tshwm sim ncaj qha tshaj plaws yog tias tam sim no tshaj qhov kev kam rau siab, thaum tej zaum yuav muaj qhov tseeb tias qhov poob hlau tshaj qhov tus qauv.

Cov txheej txheej ntawm daim ntawv hlau silicon tuab dhau, ua rau lub voj voog sib nqus dhau los ua saturated. Lub sijhawm no, qhov nkhaus sib raug zoo ntawm qhov tsis muaj tam sim no thiab qhov hluav taws xob raug khoov heev. Qhov no kuj yog ib qho tseem ceeb hauv kev tsim khoom thiab ua cov txheej txheem ntawm cov ntawv hlau silicon.

Thaum lub sijhawm tsim khoom thiab ua cov hlau cores, qhov kev taw qhia ntawm cov hlau silicon steel punching thiab shearing nto txuas yuav raug puas tsuaj, ua rau muaj kev nce ntxiv ntawm cov hlau poob nyob rau hauv tib lub magnetic induction; Rau cov motors zaus hloov pauv, cov hlau poob ntxiv los ntawm harmonics kuj yuav tsum tau xav txog; Qhov no yog ib qho tseem ceeb uas yuav tsum tau xav txog tag nrho hauv cov txheej txheem tsim.

Ntxiv rau cov yam saum toj no, tus nqi tsim ntawm lub cev muaj zog hlau poob yuav tsum yog raws li qhov tseeb tsim thiab ua cov hlau tseem ceeb, thiab txhua yam kev rau siab yuav tsum tau ua kom ntseeg tau tias tus nqi theoretical phim tus nqi tiag tiag. Cov kab nkhaus yam ntxwv muab los ntawm cov neeg muab khoom siv dav dav yog ntsuas siv txoj kev Epstein square coil, tab sis qhov kev taw qhia magnetization ntawm ntau qhov sib txawv hauv lub cev muaj zog yog txawv, thiab qhov tshwj xeeb tig hlau poob no tsis tuaj yeem xav txog tam sim no. Qhov no tuaj yeem ua rau muaj ntau qib ntawm kev tsis sib xws ntawm cov nqi xam thiab ntsuas.

Cov txheej txheem rau kev txo cov hlau poob hauv kev tsim qauv engineering

Muaj ntau txoj hauv kev los txo kev siv hlau hauv kev tsim kho, thiab qhov tseem ceeb tshaj plaws yog kho cov tshuaj rau qhov xwm txheej. Tau kawg, nws tsis yog hais txog kev siv hlau xwb, tab sis kuj yog hais txog lwm yam kev poob. Txoj hauv kev tseem ceeb tshaj plaws yog paub cov laj thawj rau kev poob hlau ntau, xws li qhov sib nqus siab, zaus siab, lossis kev saturation hauv zos ntau dhau. Tau kawg, hauv txoj kev ib txwm, ntawm ib sab tes, nws yog qhov tsim nyog los mus ze rau qhov tseeb ze li sai tau los ntawm sab simulation, thiab ntawm qhov tod tes, cov txheej txheem yog ua ke nrog thev naus laus zis los txo kev siv hlau ntxiv. Txoj kev siv ntau tshaj plaws yog kom nce kev siv cov ntawv hlau silicon zoo, thiab tsis hais tus nqi, cov hlau super silicon tuaj yeem xaiv tau. Tau kawg, kev tsim cov thev naus laus zis tshiab hauv tsev tau tsav kev txhim kho zoo dua hauv cov dej ntws thiab cov dej ntws. Cov chaw tsim hlau hauv tsev kuj tseem tab tom tsim cov khoom siv hlau silicon tshwj xeeb. Genealogy muaj kev faib tawm zoo ntawm cov khoom rau ntau yam kev siv. Nov yog ob peb txoj hauv kev yooj yim kom ntsib:

1. Txhim kho lub voj voog sib nqus

Kev ua kom lub voj voog sib nqus zoo dua, kom meej meej, yog kev ua kom lub sine ntawm lub zog sib nqus zoo dua. Qhov no tseem ceeb heev, tsis yog rau cov cav induction zaus ruaj khov xwb. Cov cav induction zaus hloov pauv thiab cov cav synchronous yog qhov tseem ceeb heev. Thaum kuv ua haujlwm hauv kev lag luam tshuab textile, kuv tau ua ob lub cav nrog kev ua tau zoo sib txawv los txo cov nqi. Tau kawg, qhov tseem ceeb tshaj plaws yog qhov muaj lossis tsis muaj cov ncej skewed, uas ua rau muaj cov yam ntxwv sinusoidal tsis sib xws ntawm lub zog sib nqus sib txawv. Vim yog ua haujlwm ntawm qhov ceev ceev, qhov poob hlau suav rau qhov feem ntau, ua rau muaj qhov sib txawv tseem ceeb hauv qhov poob ntawm ob lub cav. Thaum kawg, tom qab qee qhov kev xam rov qab, qhov sib txawv ntawm qhov poob hlau ntawm lub cav nyob rau hauv kev tswj hwm algorithm tau nce ntau dua ob zaug. Qhov no kuj tseem ceeb rau txhua tus kom txuas cov algorithms tswj hwm thaum ua cov cav tswj hwm zaus hloov pauv dua.

2. Txo qhov sib nqus ceev

Ua kom ntev ntawm lub plawv hlau lossis ua kom thaj chaw sib nqus ntawm lub voj voog sib nqus nce ntxiv kom txo qhov ceev ntawm cov hlau nplaum, tab sis cov hlau siv hauv lub cev muaj zog nce ntxiv raws li ntawd;

3. Txo qhov tuab ntawm cov hlau chips kom txo qhov poob ntawm tam sim no induced

Hloov cov ntawv hlau silicon kub-kuav los ntawm cov ntawv hlau silicon txias-kuav tuaj yeem txo qhov tuab ntawm cov ntawv hlau silicon, tab sis cov hlau nyias nyias yuav ua rau cov hlau ntau ntxiv thiab cov nqi tsim khoom ntawm lub cev muaj zog;

4. Siv cov ntawv hlau silicon txias uas muaj kev sib nqus zoo los txo qhov poob hysteresis;

5. Txais yuav cov txheej txheem rwb thaiv tsev hlau ua haujlwm siab;

6. Kev kho cua sov thiab kev tsim khoom siv tshuab

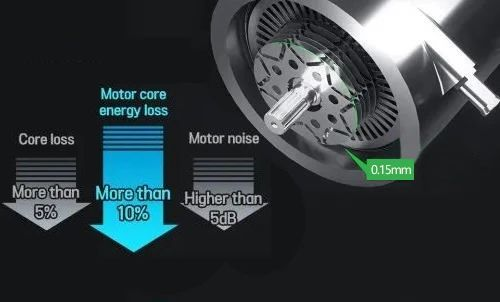

Qhov kev ntxhov siab tom qab ua cov hlau txiav tuaj yeem cuam tshuam loj heev rau qhov poob ntawm lub cev muaj zog. Thaum ua cov ntawv hlau silicon, qhov kev taw qhia txiav thiab kev ntxhov siab ntawm kev xuas nrig ntaus muaj feem cuam tshuam loj heev rau qhov poob ntawm lub plawv hlau. Kev txiav raws qhov kev taw qhia ntawm cov ntawv hlau silicon thiab ua kev kho cua sov rau ntawm cov ntawv hlau silicon tuaj yeem txo qhov poob los ntawm 10% txog 20%.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-01-2023