Lublub cev muaj zogtus ncej yog hollow, nrog kev ua haujlwm zoo dissipation cua sov thiab tuaj yeem txhawb nqa lub teeb ntawmlub cev muaj zog.Yav tas los, cov ncej ntawm lub cev muaj zog feem ntau yog khov kho, tab sis vim yog siv cov ncej ntawm lub cev muaj zog, qhov kev ntxhov siab feem ntau tau tsom mus rau ntawm qhov chaw ntawm lub ncej, thiab qhov kev ntxhov siab ntawm lub hauv paus yog qhov me me. Raws li cov khoom khoov thiab torsional ntawm cov khoom siv kho tshuab, sab hauv ntawmlub cev muaj zogTus ncej tau raug hollowed tawm kom raug, thiab tsuas yog xav tau ib qho me me sab nraud kom nce qhov sab nraud. Tus ncej hollow tuaj yeem ua tau raws li kev ua tau zoo thiab kev ua haujlwm zoo li tus ncej khov kho, tab sis nws qhov hnyav tuaj yeem txo qis heev. Lub caij no, vim yog qhov hollowing ntawmlub cev muaj zogtus ncej, roj txias tuaj yeem nkag mus rau sab hauv ntawm lub cev muaj zog, ua rau thaj chaw tso cua sov ntau ntxiv thiab txhim kho kev ua haujlwm tso cua sov kom zoo dua. Nyob rau hauv qhov sib txawv tam sim no ntawm 800V high-voltage them ceev ceev, qhov zoo ntawm cov ncej cav hollow yog ntau dua. Cov txheej txheem tsim khoom tam sim no rau cov ncej cav hollow feem ntau suav nrog cov ncej khov kho hollowing, vuam, thiab kev sib xyaw ua ke, ntawm cov uas vuam thiab kev sib xyaw ua ke siv dav hauv kev tsim khoom.

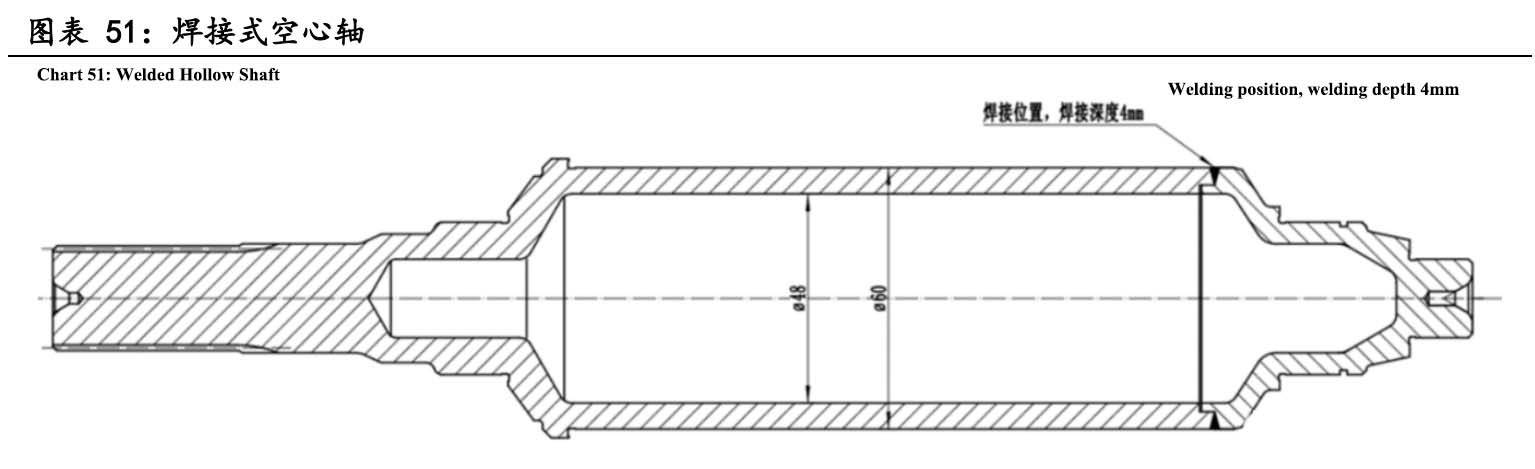

Lub qhov hollow welded feem ntau yog ua tiav los ntawm kev extrusion forming kom ua tiav lub qhov sab hauv ntawm lub qhov, thiab tom qab ntawd machined thiab welded rau hauv cov duab. Los ntawm extrusion molding, cov duab hloov pauv ntawm lub qhov sab hauv nrog cov qauv khoom thiab lub zog xav tau khaws cia ntau li ntau tau. Feem ntau, qhov tuab ntawm phab ntsa ntawm cov khoom tuaj yeem tsim hauv qab 5 hli. Cov khoom siv vuam feem ntau siv kev sib txhuam vuam lossis laser vuam. Yog tias siv kev sib txhuam vuam, qhov chaw ntawm lub pob qij txha feem ntau yog li 3 hli vuam protrusion. Siv laser vuam, qhov tob vuam feem ntau yog ntawm 3.5 thiab 4.5 hli, thiab lub zog vuam tuaj yeem lav tias yuav ntau dua 80% ntawm lub substrate. Qee tus neeg muag khoom tuaj yeem ua tiav ntau dua 90% ntawm lub zog substrate los ntawm kev tswj hwm cov txheej txheem nruj. Tom qab vuam ntawm lub qhov hollow tiav lawm, nws yog qhov tsim nyog los ua qhov kev sim ultrasonic lossis X-ray ntawm microstructure thiab weld zoo ntawm thaj chaw vuam kom ntseeg tau tias cov khoom sib xws.

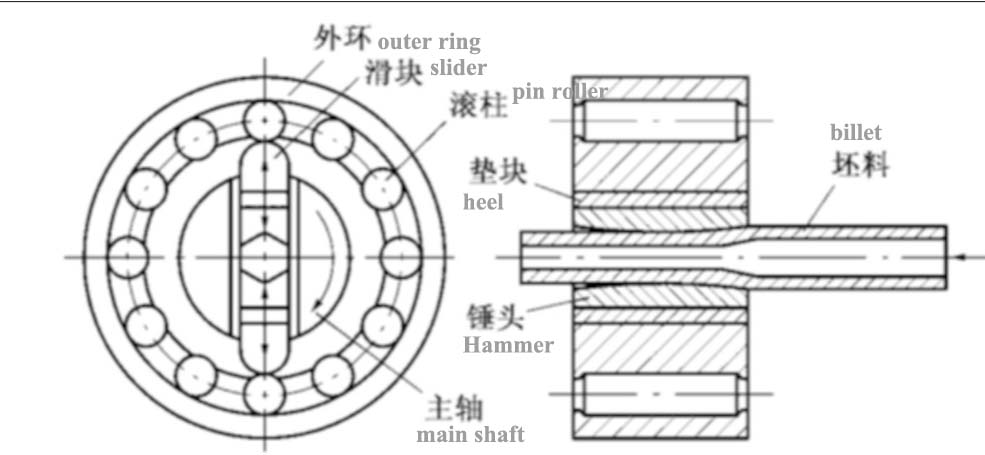

Lub hollow shaft uas sib xyaw ua ke feem ntau yog forged los ntawm cov khoom siv sab nraud ntawm qhov khoob, ua rau sab hauv kom ncaj qha ua tiav lub qhov sab hauv ntawm lub qhov. Tam sim no, radial forging thiab rotary forging feem ntau yog siv, thiab cov khoom siv feem ntau yog imported. Radial forging yog ib txwm muaj ntawm FELLS lub tuam txhab cov khoom siv, thaum lub rotary forging yog ib txwm muaj ntawm GFM lub tuam txhab cov khoom siv. Radial forging forming feem ntau yog ua tiav los ntawm kev siv plaub lossis ntau dua symmetrical hammers ntawm zaus ntawm ntau dua 240 lub tshuab ib feeb kom ua tiav me me deformation ntawm qhov khoob thiab ncaj qha hollow tube blank forming. Rotary forging forming yog cov txheej txheem ntawm kev npaj ntau lub taub hau rauj hauv qhov kev taw qhia ntawm billet. Lub taub hau rauj tig ib ncig ntawm lub axis thaum ua radial high-frequency forging ntawm qhov workpiece, txo qhov loj me ntawm billet thiab txuas ntxiv axially kom tau txais qhov workpiece. Piv rau cov khoom siv khov kho ib txwm muaj, tus nqi tsim khoom ntawm cov hollow shafts sib xyaw ua ke yuav nce ntxiv txog 20%, tab sis qhov hnyav ntawm lub cev muaj zog feem ntau yuav txo qis los ntawm 30-35%.

Lub sijhawm tshaj tawm: Cuaj hlis-15-2023